Pool Chiller Repair

Restore Proper Cooling and System Performance

Understanding Pool Chillers: How They Work and Why They Matter

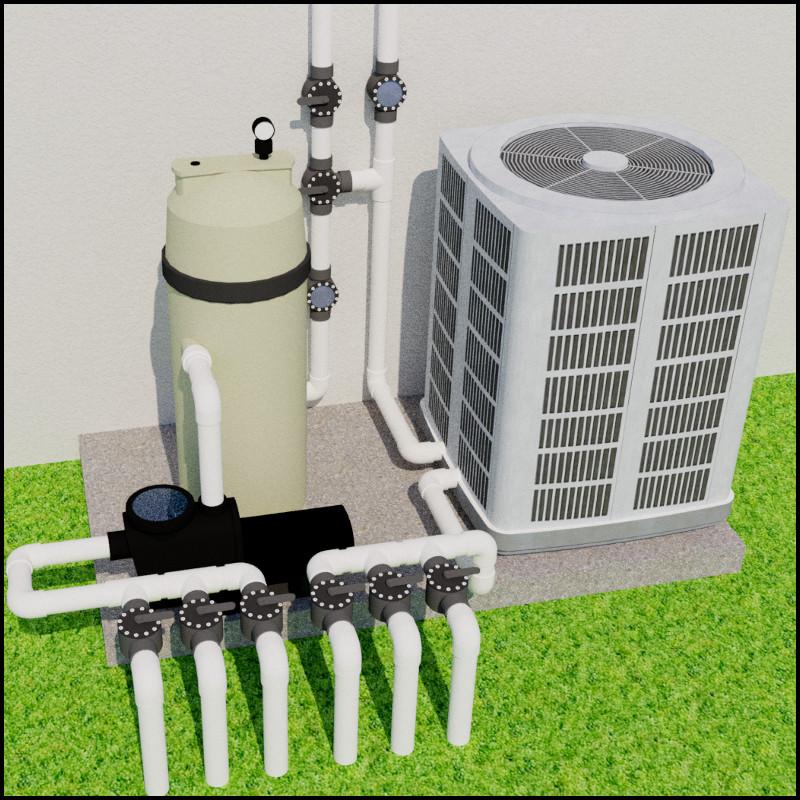

A pool chiller is essentially an air conditioner for your pool water. While most people are familiar with pool heaters that warm water, chillers perform the opposite function they remove heat from your pool water to maintain comfortable swimming temperatures during hot weather. This becomes especially important in regions where summer temperatures regularly exceed 90°F, as pool water can quickly become bath-like and uncomfortable, sometimes reaching 90-95°F or higher without cooling intervention.

Pool chillers operate on the same basic principle as your home’s air conditioning system or refrigerator. They use a refrigeration cycle that involves compressing and expanding refrigerant to absorb heat from the pool water and release it into the surrounding air. The system consists of several key components: a compressor, condenser, evaporator, expansion device, and circulation pump, all controlled by sophisticated electronics that monitor and regulate temperature.

Why Proper Chiller Function Matters

When your pool chiller isn’t working correctly, several problems emerge:

Swimmer discomfort: Water temperatures above 88°F become increasingly unpleasant and can even pose health risks during vigorous exercise

Chemical inefficiency: Warmer water accelerates chlorine consumption and can promote algae and bacteria growth

Equipment stress: Other pool equipment, particularly pumps and filters, work harder in warmer water conditions

Increased costs: Running a malfunctioning chiller consumes more energy while delivering less cooling

Limited pool use: During heat waves, an uncooled pool may become unusable during daylight hours

Recognizing Chiller Problems: Warning Signs You Shouldn't Ignore

Temperature-Related Symptoms

Inadequate Cooling Performance:

Water temperature consistently higher than setpoint

Chiller runs constantly but temperature drops very slowly

Temperature varies dramatically throughout the day

Cooling capacity seems diminished compared to previous seasons

Temperature Control Issues:

Chiller doesn’t respond to thermostat adjustments

Temperature swings more than 3-4 degrees from setpoint

System cycles on and off too frequently

Different areas of pool have significantly different temperatures

Operational and Performance Signs

Extended Run Times:

Chiller runs continuously during hot weather without achieving desired temperature

Run times are significantly longer than in previous seasons

System never seems to reach “satisfied” condition

Reduced Cooling Capacity:

Noticeably less cool air coming from unit during operation

Water temperature drop per hour is less than expected

System struggles to maintain temperature during peak heat

Audible and Visual Warning Signs

Unusual Noises:

Grinding or screeching from compressor area

Unusual fan noises (clicking, rattling, uneven operation)

Loud humming or buzzing that wasn’t present before

Pinging or knocking sounds during operation

Visual Indicators:

Ice formation on coils or refrigerant lines

Oil stains or refrigerant leaks around connections

Corrosion on electrical connections or cabinet

Water leaks from drain lines or connections

Unusual vibration during operation

Control and Display Issues:

Error codes on control panel

Display not functioning properly

Buttons not responding as expected

Automation system reporting chiller faults

System Integration Problems

Communication Failures:

Chiller not responding to automation system commands

Temperature sensors reporting inaccurate readings

Integration with pool pump or other equipment failing

Smartphone app unable to connect or control chiller

Water Flow Issues:

Reduced water flow through the system

Pressure gauge readings outside normal range

Water temperature difference across chiller too small

Air bubbles in water lines to/from chiller

Common Pool Chiller Problems and Their Underlying Causes

Compressor Issues: The Heart of the System

Compressor Failure:

Electrical failures: Burned windings, failed capacitors, or relay problems

Mechanical failures: Seized bearings, broken valves, or internal damage

Overheating: Insufficient cooling, refrigerant issues, or electrical problems

Short cycling: Rapid on/off cycling that stresses the compressor

Compressor Performance Problems:

Reduced capacity: Not pumping refrigerant efficiently

Excessive noise: Worn internal components or mounting issues

High amp draw: Working harder than designed, often due to system issues

Tripping breakers: Electrical problems or mechanical overload

Refrigerant System Problems

Refrigerant Issues:

Low refrigerant charge: Leaks in the system reduce cooling capacity

Overcharge: Too much refrigerant can cause multiple problems

Contamination: Moisture, air, or debris in the refrigerant circuit

Wrong refrigerant type: Incorrect refrigerant for the system

Refrigerant Flow Problems:

Restricted flow: Blocked filter driers, expansion devices, or lines

Poor heat transfer: Dirty coils or incorrect refrigerant charge

Flash gas in liquid line: Caused by restrictions or improper charge

Heat Exchange Problems

Condenser Issues:

Dirty coils: Reduced airflow and heat rejection

Fan problems: Failed motors, bad capacitors, or damaged blades

Airflow restrictions: Blocked intake or exhaust areas

Corrosion: Especially in coastal or chemical-exposed areas

Evaporator Problems:

Scale buildup: Mineral deposits from pool water

Fouling: Organic growth or debris in water passages

Corrosion: Chemical attack from pool water

Freezing: Low refrigerant or water flow causing ice formation

Water System Issues

Flow Problems:

Insufficient flow: Pump issues, clogged filters, or valve problems

Excessive flow: Can reduce heat transfer efficiency

Air in system: Causes noise and reduces heat transfer

Pressure problems: High or low pressure indicating system issues

Water Quality Issues:

Scale formation: Hard water causing mineral deposits

Chemical damage: Improper water chemistry attacking components

Biological growth: Algae or bacteria in water passages

Debris accumulation: Sand, leaves, or other contaminants

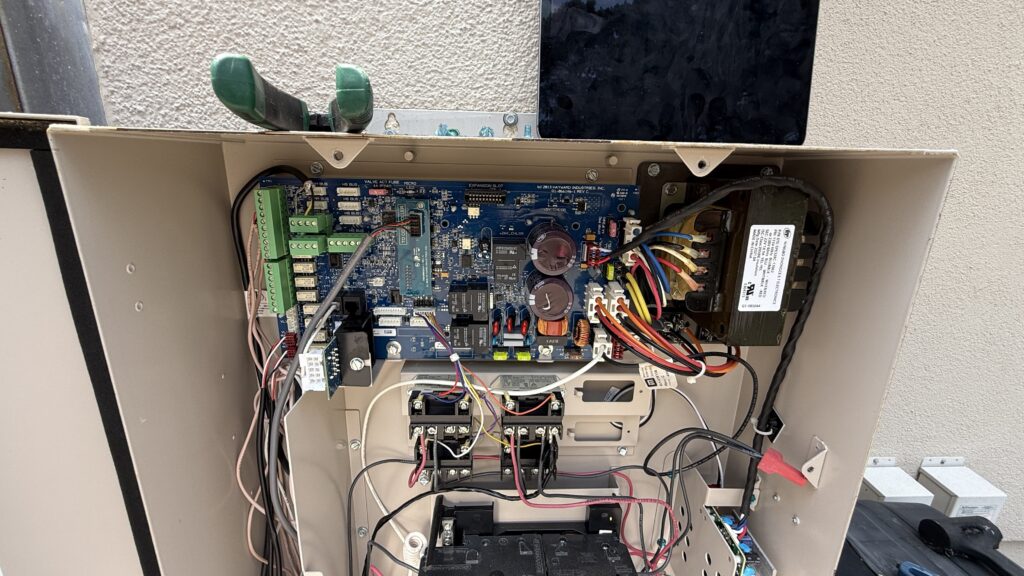

Electrical and Control Problems

Control System Failures:

Board failures: Burned components or failed circuitry

Sensor problems: Temperature, pressure, or flow sensors failing

Communication issues: With automation systems or remote controls

Programming errors: Incorrect setup or corrupted memory

Electrical Component Failures:

Contactors and relays: Burned contacts or failed coils

Capacitors: Failed start or run capacitors

Wiring issues: Corrosion, loose connections, or damaged insulation

Safety devices: Tripped or failed high-pressure switches, thermal cutouts

Our Comprehensive Chiller Repair Process

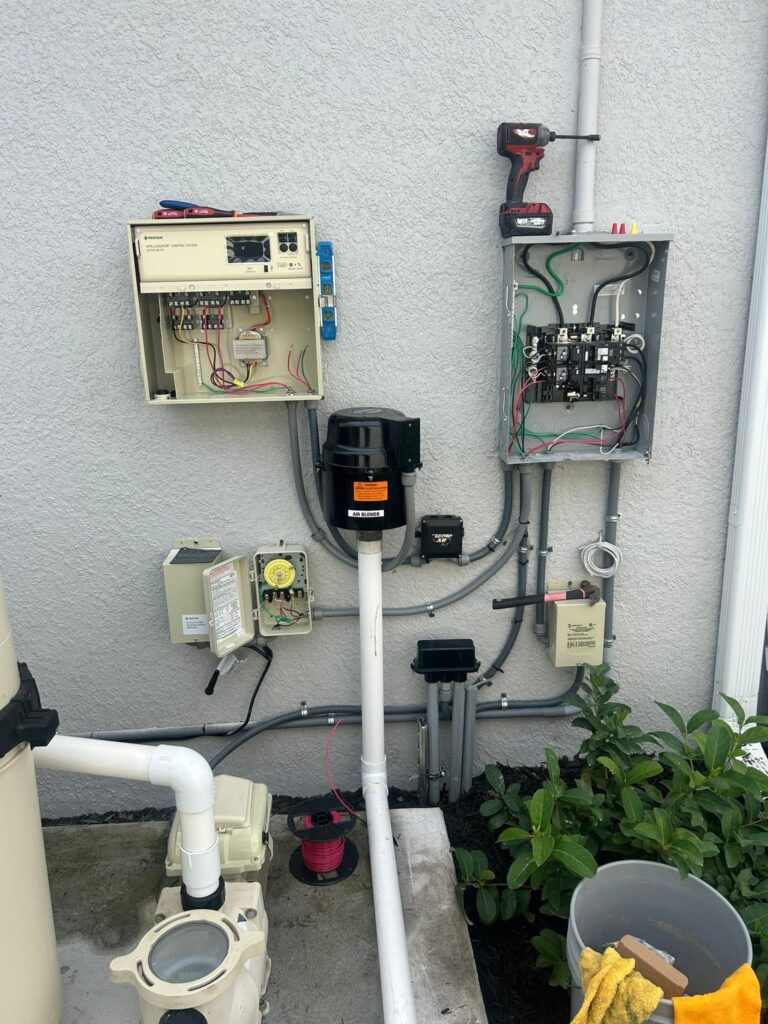

Phase 1: Detailed Inspection and Precise Diagnosis

Initial Assessment:

We begin with a thorough visual inspection of the entire chiller system, including:

External examination: Checking for physical damage, corrosion, or leaks

Control system review: Reading error codes, checking settings, testing controls

Operational observation: Watching startup, listening for unusual sounds, observing cycling patterns

Performance Testing:

We conduct systematic testing to measure actual performance:

Temperature measurements: Water in/out temperatures, ambient air temperature

Pressure readings: Refrigerant high and low side pressures

Electrical measurements: Voltage, amperage, capacitor testing

Flow verification: Water flow rate and pressure drop across chiller

Cycle analysis: Monitoring on/off cycles and run times

Advanced Diagnostics:

For complex problems, we employ specialized diagnostic tools:

Refrigerant leak detection: Electronic detectors, ultraviolet dye, or bubble testing

Compressor analysis: Megohm testing, winding resistance, performance curves

Control system diagnostics: Computer interface tools for communicating with control boards

Thermal imaging: Identifying hot spots, cold spots, or refrigerant restrictions

Phase 2: Clear Communication and Repair Planning

Understanding Your Situation:

We take time to understand:

Your usage patterns and cooling needs

Any changes in performance you’ve noticed

Previous repairs or maintenance history

Your budget considerations and priorities

Explaining the Problem:

We provide clear explanations in plain language:

What’s specifically wrong with your chiller

Why the problem occurred

How it affects cooling performance

What happens if it’s not repaired

Presenting Options:

We offer comprehensive repair options:

Immediate repair: Fixing the specific problem identified

Preventive measures: Addressing potential future issues while we’re working

Efficiency improvements: Upgrades that can improve performance or reduce operating costs

Replacement consideration: When repair may not be the most cost-effective solution

Phase 3: Professional Repair Execution

Safe Work Practices:

Electrical safety: Proper lockout/tagout procedures, verification of de-energization

Refrigerant handling: EPA-certified technicians, proper recovery and charging

Worksite safety: Protection of property, proper tool use, clean work practices

Quality Repair Standards:

Manufacturer procedures: Following specific repair guidelines for your equipment

Quality components: Using OEM or equivalent quality replacement parts

Proper techniques: Correct installation, torquing, and sealing of all components

Documentation: Recording all work performed, parts used, and measurements taken

Specialized Repair Procedures:

Compressor replacement: Proper refrigerant recovery, oil management, system cleaning

Coil repair: Careful cleaning, leak repair, pressure testing

Electrical repairs: Correct wiring, proper terminations, insulation testing

Control system repairs: Board replacement, sensor calibration, programming

Phase 4: Comprehensive Testing and Verification

System Testing:

Leak testing: Verifying all repairs are leak-free

Electrical testing: Checking all circuits and safety devices

Performance verification: Measuring cooling capacity and efficiency

Safety system check: Testing all safety switches and controls

Operational Validation:

Startup sequence: Verifying proper startup and shutdown

Temperature control: Testing thermostat accuracy and response

Cycle testing: Monitoring on/off cycles for proper operation

Integration testing: Ensuring proper communication with other pool equipment

Final Verification:

Customer demonstration: Showing you how the system now operates

Performance documentation: Providing before/after measurements

Maintenance guidance: Explaining any new maintenance requirements

Warranty information: Reviewing warranty coverage on parts and labor

Special Considerations for Different Pool Types

Saltwater Pools

Additional challenges:

Increased corrosion potential

Chemical compatibility issues

Different maintenance requirements

Potential for scale formation

Our specialized approach:

Using corrosion-resistant replacement parts

Additional protective measures

Specific cleaning and maintenance recommendations

Experience with saltwater system interactions

Indoor Pools

Unique considerations:

Different heat load calculations

Humidity control interactions

Air quality considerations

Year-round operation demands

Our expertise:

Understanding indoor pool thermodynamics

Coordinating with building HVAC systems

Addressing humidity-related issues

Year-round maintenance planning

Competition and Therapy Pools

Critical requirements:

Precise temperature control

High reliability needs

Specific temperature ranges

Regulatory compliance

Our capabilities:

Precision calibration and control

Backup system considerations

Compliance documentation

Specialized temperature sensors and controls

Commercial and Public Pools

Additional requirements:

Higher reliability demands

Regulatory compliance

Usage pattern considerations

Maintenance scheduling around operations

Our experience:

Working with commercial-grade equipment

Understanding health department requirements

Off-hours repair scheduling

Preventative maintenance programs

Cost Considerations and Value Analysis

Factors Affecting Repair Costs

Problem Complexity:

Simple component replacement vs. major system repair

Accessibility of failed components

Need for specialized tools or equipment

Diagnostic time required

Parts Requirements:

Compressor replacement (typically most expensive part)

Control board replacement

Coil repair or replacement

Refrigerant requirements

Labor Intensity:

Time required for diagnosis

Repair complexity and duration

Need for multiple technicians

Site-specific challenges

Typical Repair Cost Ranges

Minor Repairs ($150 – $500):

Capacitor replacement

Contactor or relay replacement

Sensor replacement

Minor electrical repairs

Moderate Repairs ($500 – $1,500):

Fan motor replacement

Control board repair

Major electrical component replacement

Refrigerant leak repair and recharge

Major Repairs ($1,500 – $3,500+):

Compressor replacement

Coil replacement

Complete electrical system overhaul

Multiple component failures

Cost Comparison: Repair vs. Replacement

When Repair Makes Financial Sense:

Repair cost less than 50% of replacement cost

Chiller less than 7-10 years old

Good maintenance history

No repeated failures

Still under warranty

When Replacement May Be Better:

Repair approaching 50-70% of replacement cost

Multiple systems failing simultaneously

Obsolete or unavailable parts

Inefficient older technology

Frequent breakdowns

Energy Efficiency Considerations:

Newer chillers often 20-40% more efficient

Energy savings may justify replacement

Utility rebates sometimes available for efficiency upgrades

Long-term operating cost comparison

Preventative Maintenance: Avoiding Costly Repairs

Regular Maintenance Tasks

Monthly Checks (Homeowner):

Visual inspection for leaks or damage

Cleaning debris from around unit

Checking that fans are operating properly

Listening for unusual noises

Seasonal Maintenance (Professional):

Spring Startup:

System inspection and testing

Cleaning coils and components

Checking refrigerant charge

Verifying control operation

Testing safety devices

During Season:

Regular cleaning as needed

Monitoring performance

Addressing minor issues promptly

Water chemistry maintenance

Fall Shutdown:

Proper system shutdown

Winterization if needed

Off-season protection

Planning for next season

Professional Maintenance Program

What Our Maintenance Includes:

Comprehensive inspection: All components checked

Performance testing: Actual cooling capacity measurement

Cleaning services: Coils, filters, and components

Electrical testing: Components and connections

Refrigerant check: Pressure and charge verification

Control calibration: Temperature and safety controls

Documentation: Performance records and recommendations

Benefits of Professional Maintenance:

Early problem detection

Maintained efficiency

Extended equipment life

Warranty compliance

Reduced emergency repairs

Energy Efficiency and Performance Optimization

Improving Chiller Efficiency

Maintenance Impact:

Clean coils improve heat transfer

Proper refrigerant charge maximizes efficiency

Good airflow reduces compressor load

Calibrated controls prevent overcooling

Operational Optimization:

Proper temperature setpoints

Smart scheduling based on usage

Integration with pool cover use

Coordination with other pool equipment

System Upgrades:

Variable speed compressors or fans

Improved controls and sensors

Better insulation on refrigerant lines

High-efficiency replacement components

Monitoring Performance

Key Performance Indicators:

Temperature drop per hour

Energy consumption per degree cooled

Run time percentage

Cycling frequency

Performance Tracking:

Regular measurement and recording

Comparison to manufacturer specifications

Tracking changes over time

Identifying degradation before failure

Safety Considerations in Chiller Repair

Electrical Safety

High voltage hazards: Proper lockout/tagout procedures

Capacitor discharge: Safe handling of stored energy

Grounding verification: Ensuring proper equipment grounding

Circuit protection: Proper fuses and breakers

Refrigerant Safety

EPA regulations: Proper handling and certification

Pressure hazards: Safe working with pressurized systems

Chemical exposure: Proper handling and ventilation

Environmental protection: Preventing releases

Worksite Safety

Trip hazards: Keeping work areas organized

Overhead hazards: Working safely around installed equipment

Weather considerations: Safe work in various conditions

Customer protection: Keeping pool areas safe during repairs

Types of Pool Chillers We Repair

Air-Cooled Chillers

How they work: Use fans to blow ambient air across condenser coils to reject heat

Common applications: Most residential pools, some commercial installations

Typical problems: Dirty coils, fan failures, airflow restrictions, corrosion

Repair considerations: Often located outdoors, exposed to weather elements

Water-Cooled Chillers

How they work: Use cooling water (often from a cooling tower or well water) to reject heat

Common applications: Larger commercial pools, areas with water availability

Typical problems: Water treatment issues, scale buildup, pump failures

Repair considerations: Additional water system components to maintain

Heat Pump/Chiller Combos

How they work: Reversible systems that can both heat and cool pool water

Common applications: Pools needing both heating and cooling capabilities

Typical problems: Reversing valve issues, dual-function control problems

Repair considerations: More complex systems with additional components

Portable Chillers

How they work: Smaller, movable units often used for temporary or supplemental cooling

Common applications: Special events, therapy pools, temporary installations

Typical problems: Hose connection issues, mobility damage, smaller component failures

Repair considerations: Often less serviceable, may require more frequent maintenance

Commercial-Scale Chillers

How they work: Larger capacity systems for public pools, water parks, or multiple pools

Common applications: Community pools, hotels, aquatic centers

Typical problems: Multiple compressor systems, complex controls, heavy usage issues

Repair considerations: Often require specialized training and tools

Why Choose Us for Pool Automation Installation?

Inspection & Diagnostics

We perform a thorough evaluation of your chiller, checking electrical components, refrigerant systems, water flow, and controls to pinpoint the exact cause of the problem.

Clear Repair Plan

Once diagnosed, we explain the issue in plain language and outline the recommended repair options, expected performance results, and any preventative steps.

Professional Repair

Repairs are completed using manufacturer-approved parts and proper calibration procedures to restore accurate temperature control and efficient operation.

System Verification

After repairs are complete, we run full operational tests to ensure consistent cooling, safe electrical performance, and proper integration with existing pool equipment.

FAQS

How long should a pool chiller last?

Typical lifespan: 10-15 years with proper maintenance

Factors affecting lifespan:

Maintenance quality and frequency

Environmental conditions

Usage patterns and hours

Water chemistry management

Initial installation quality

Can I run my chiller with a solar cover on?

Generally not recommended because:

Covers trap heat, making chiller work harder

Reduced evaporation actually reduces natural cooling

Can cause the chiller to run excessively

May lead to premature component failure

Better approach: Use cover at night to retain cooling, remove during chiller operation

How much does it cost to run a pool chiller?

Variable factors:

Chiller size and efficiency

Desired temperature vs. ambient temperature

Hours of operation

Local electricity rates

Pool size and heat gain factors

Typical range: $50-$300 per month during cooling season

Energy-saving tips: Use at night, maintain proper temperature, ensure good maintenance

Can I repair my chiller myself?

Not recommended for most repairs because:

Specialized tools and knowledge required

Refrigerant handling requires EPA certification

Electrical hazards can be serious

Incorrect repairs can cause additional damage

May void manufacturer warranties

What homeowners can do:

Keep area around chiller clean

Monitor performance and report changes

Change air filters if applicable

Schedule professional maintenance

What temperature should I set my pool chiller to?

Comfort range: Typically 78-85°F for most swimmers

Factors to consider:Personal preference

Activity level (cooler for exercise)

Humidity levels (cooler feels more comfortable in high humidity)

Time of day (warmer in morning, cooler in afternoon heat)

Energy consumption (each degree cooler increases energy use)

Investing in Comfort and Reliability

A properly functioning pool chiller transforms your summer swimming experience, turning what could be an uncomfortably warm pool into a refreshing oasis. When your chiller isn’t working correctly, professional repair restores not just cooling capacity but also energy efficiency, equipment protection, and peace of mind.

The key to chiller longevity and reliability is prompt attention to problems combined with regular professional maintenance. Small issues addressed early prevent major failures during peak cooling season when you need your chiller most.

Whether you’re dealing with a complete breakdown or just noticing reduced performance, professional diagnosis and repair ensure your chiller operates efficiently and reliably throughout the swimming season.

service Areas

We provide professional pool chiller repair across North Texas, including Frisco, Plano, McKinney, Allen, and surrounding communities.