Pool Filter Repair

Professional Pool Filter Repair for Clean, Safe, and Efficient Pools

The Complete Guide to Professional Pool Filter Repair: Ensuring Clean, Safe, and Efficient Swimming Environments

A crystal-clear swimming pool is the centerpiece of backyard relaxation and family fun, but that pristine appearance depends entirely on one critical component working behind the scenes: your pool filtration system. When your pool filter functions optimally, it silently and efficiently removes contaminants, debris, and microscopic particles, maintaining the chemical balance and clarity that define an inviting swimming environment. However, when this vital system begins to fail, the consequences extend far beyond cloudy water—they threaten the entire ecosystem of your pool and the equipment that sustains it. Professional pool filter repair isn’t merely a maintenance task; it’s an essential investment in protecting your pool’s health, your equipment’s longevity, and your swimmers’ safety.

The Critical Role of Your Pool Filter: More Than Just Clean Water

Your pool filter serves as the kidney of your swimming pool, continuously circulating and cleansing thousands of gallons of water. During each pump cycle, water passes through the filter media whether cartridges, sand, or diatomaceous earth which traps everything from leaves and dirt to body oils, sunscreen residues, and bacteria as small as 3-5 microns. This relentless process prevents the growth of algae, maintains chemical efficiency, and ensures water is sanitized effectively.

When filtration is compromised, contaminants remain in suspension or circulation, leading to a cascade of problems. Cloudy water is merely the visible symptom; beneath the surface, unbalanced chemistry forces increased use of chlorine and other sanitizers, while unfiltered particles provide breeding grounds for pathogens. Furthermore, the entire hydraulic system suffers pumps must work harder against increased resistance, heaters become less efficient due to scaling and poor flow, and pipes can develop buildups that restrict circulation over time. Thus, what begins as a minor filter issue can rapidly evolve into a systemic failure affecting every component of your pool system.

The High Cost of Ignoring Pool Filter Problems

Many pool owners postpone filter repairs, viewing them as non-urgent maintenance. This misconception can lead to exponentially more expensive consequences. A malfunctioning filter doesn’t simply fail to clean water; it actively contributes to the deterioration of your entire pool system.

Chemical Imbalance and Waste: Proper filtration allows sanitizers to work efficiently. When filters fail, chlorine bonds with contaminants to form chloramines—ineffective compounds that cause eye irritation and strong odors. This requires shock treatments and additional chemicals to restore balance, increasing monthly maintenance costs by 30-50% in some cases.

Accelerated Equipment Wear: Your pool pump is designed to move water against a specific pressure range. A clogged or damaged filter increases resistance, forcing the pump to operate at higher amperage. This added strain reduces the pump’s lifespan by as much as half in severe cases. Similarly, heaters exposed to poorly filtered water accumulate scale on heat exchangers, reducing efficiency and leading to premature failure.

Energy Inefficiency: The U.S. Department of Energy notes that pool pumps account for a significant portion of residential energy use in homes with pools. A compromised filtration system can increase a pump’s energy consumption by 25-40% as it struggles to maintain circulation. This isn’t merely an equipment issue—it’s a continuous financial drain that compounds monthly.

Structural and Surface Damage: Fine particles that bypass filtration eventually settle, creating abrasive layers on pool surfaces. In plaster pools, this can lead to staining and roughness. In vinyl-lined pools, microscopic debris acts like sandpaper against the liner with each circulation cycle. For fiberglass pools, persistent cloudiness often indicates filtration failure that, if unaddressed, can lead to gel coat discoloration.

Health and Safety Concerns: Beyond aesthetics, inadequate filtration poses genuine health risks. Cryptosporidium, Giardia, and E. coli can survive in poorly filtered pools despite chlorination. Turbid water also creates drowning hazards by obscuring the pool bottom, particularly concerning for young swimmers.

Types of Pool Filters We Repair

Professional pool filter repair requires specialized knowledge of different filtration technologies. Each system cartridge, sand, and DE (diatomaceous earth) has unique components, failure points, and repair protocols. A one-size-fits-all approach doesn’t work in filtration repair, which is why expertise across all platforms is essential.

1. Cartridge Pool Filter Repair: Precision for Modern Systems

Cartridge filters have gained popularity for their excellent filtration capabilities (typically filtering down to 10-15 microns) and water conservation advantages (no backwashing required). However, their multiple pleated fabric elements and complex internal manifolds create specific failure points requiring expert attention.

Common Cartridge Filter Issues We Repair:

Torn or Collapsed Cartridges: Physical damage to the pleated fabric allows unfiltered water to bypass the media entirely. This often occurs due to improper handling, high pressure from closed valves, or simple age-related deterioration.

Clogged Elements Beyond Cleaning: While regular hosing can maintain cartridges, eventually the pores become embedded with oils and microscopic particles that cleaning cannot remove, causing persistent high pressure.

Cracked Housings or Manifolds: UV exposure, freezing temperatures, or physical impact can cause structural cracks in the filter tank or internal plastic components.

Worn O-Rings and Seals: The multiple sealing points in cartridge filters—especially between the tank halves and at the drain plug—deteriorate over time, leading to air leaks and water loss.

Pressure Gauge Failures: Faulty gauges provide inaccurate readings, preventing proper monitoring of filter condition.

Our Cartridge Filter Repair Process: We begin with a complete disassembly and inspection of all elements, not just the obviously damaged ones. Using manufacturer-approved replacement cartridges and components, we ensure proper seating and alignment of all elements on the manifold. We then lubricate and replace all O-rings with high-quality chemical-resistant variants before reassembling the tank to exact torque specifications. Finally, we perform a detailed pressure test and flow verification to ensure the repaired system operates within optimal parameters.

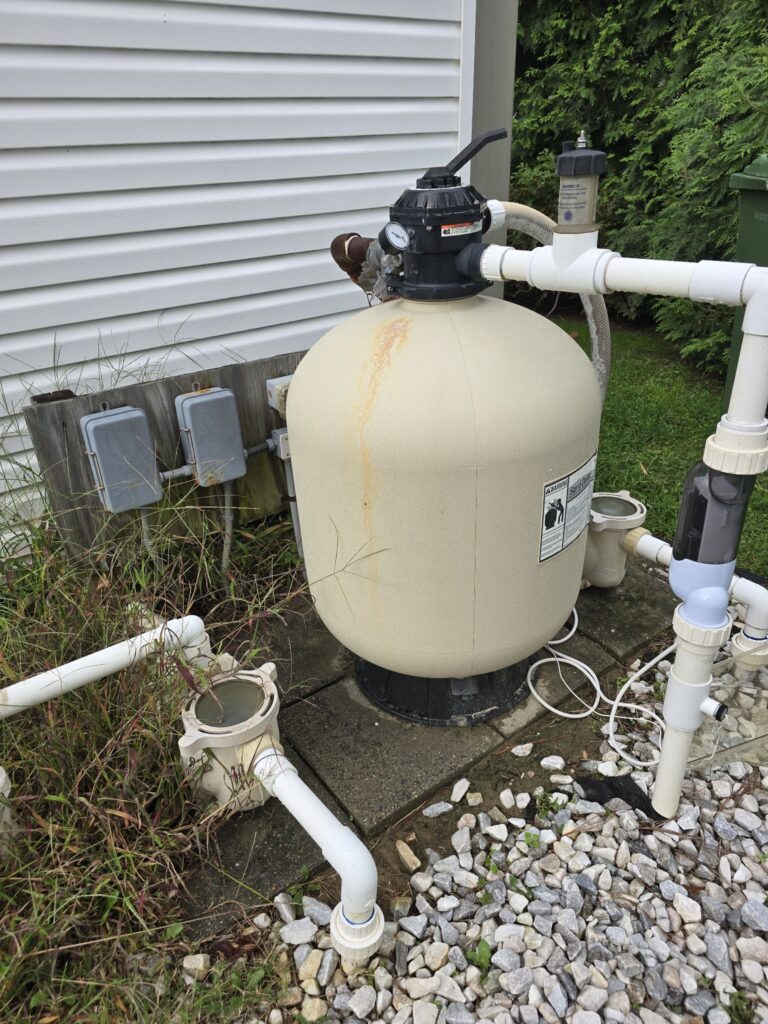

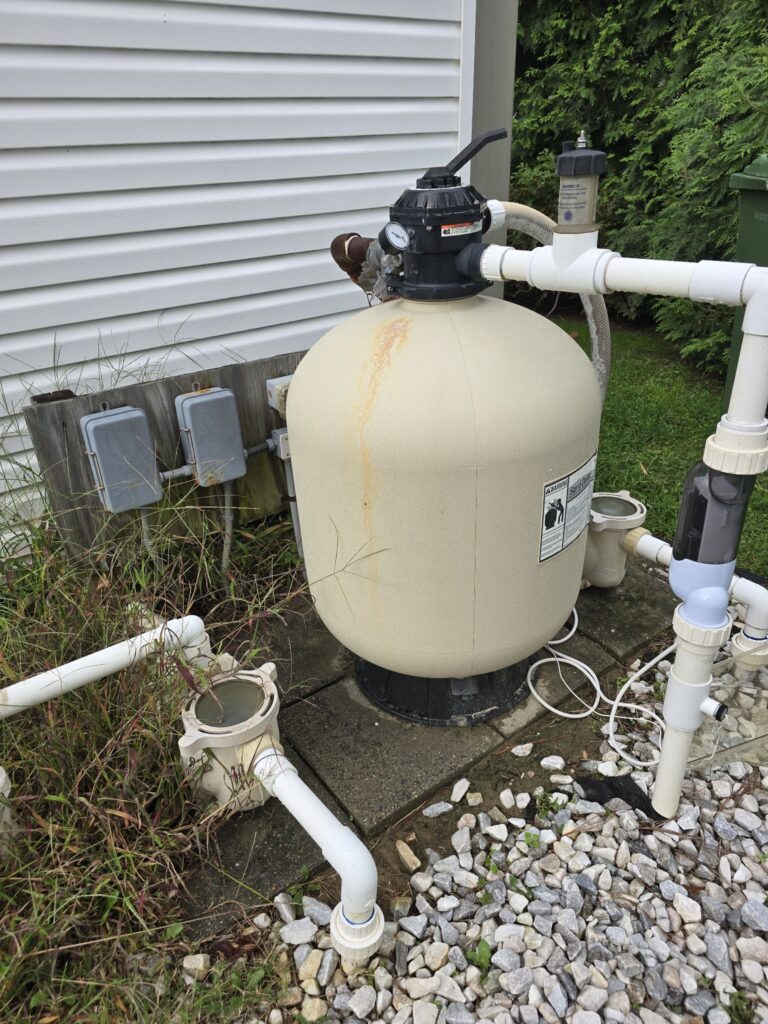

2. Sand Pool Filter Repair: Restoring Classic Filtration Performance

Sand filters represent the workhorses of the pool industry, using specially graded #20 silica sand or alternative media to trap debris. Their simplicity is both an advantage and a vulnerability—while they have fewer mechanical parts, their internal components are susceptible to specific failure modes that impact performance.

Critical Sand Filter Repairs We Perform:

Broken or Clogged Laterals: These slender pipes at the bottom of the filter tank distribute water evenly through the sand bed. When they crack or become blocked, unfiltered water enters the return lines, and sand may backflow into the pool.

Channeling and Sand Compaction: Over time, sand can form hard packed areas or channels where water takes the path of least resistance, drastically reducing filtration effectiveness.

Multiport Valve Failures: The complex valve controlling filter, backwash, rinse, and other functions contains numerous gaskets, spider gaskets, and seals that wear out, causing leaks and incorrect function.

Cracked Filter Tanks: Particularly concerning in older fiberglass tanks or those exposed to freezing conditions without proper winterization.

Sand Replacement and Media Upgrades: Sometimes repair involves replacing the entire sand bed with fresh media or upgrading to glass filter media for improved filtration and longer life.

Our Sand Filter Restoration Approach: We don’t just address the obvious issue—we perform comprehensive diagnostics. This includes checking the sand bed for proper depth and condition, inspecting each lateral for hairline cracks, and testing the multiport valve in every position. For valve repairs, we use complete rebuild kits rather than piecemeal gasket replacements, ensuring all wearing components are renewed simultaneously. When sand replacement is needed, we vacuum out the old media completely before installing new, ensuring no residual debris contaminates the fresh bed.

3. DE (Diatomaceous Earth) Filter Repair: Expert Care for Superior Filtration

DE filters provide the finest level of filtration available to residential pools, trapping particles as small as 3-5 microns. Their complex grid arrays and precise operational requirements make them particularly vulnerable to performance issues when not properly maintained or repaired.

DE Filter Specific Repairs We Specialize In:

Torn Grids or Fingers: The fabric covering the plastic grid framework is delicate and can develop rips from improper cleaning, high pressure, or age, allowing DE powder to bypass into the pool.

Manifold and Spine Damage: The central assembly that holds the grid array must maintain perfect alignment; cracks or warping here cause uneven DE coating and filtration failure.

Air Relief System Failures: DE filters require proper air bleeding during startup; faulty air relief valves cause airlocks that reduce efficiency and potentially damage grids.

Backwash Valve and Separation Tank Issues: For regenerative DE systems, the complex piping and separation tanks require precise adjustment and sealing to function properly.

DE Powder Clumping and Inefficient Coating: Often mistaken for mechanical failure, improper DE preparation or application leads to poor performance that mimics component damage.

Our DE Filter Precision Repair Methodology: DE filter repair demands meticulous attention to detail. We carefully remove and inspect each grid individually under good lighting, checking both the fabric covering and the structural integrity of the plastic framework. We reassemble grids in the exact sequence and orientation specified by the manufacturer, ensuring equal spacing and tension. After reassembly, we perform a thorough pre-coating procedure and monitor pressure rise during the initial filtration cycle to verify proper DE deposition across all grids.

4. Beyond the Filter: Systemic Diagnosis for Lasting Solutions

Professional pool filter repair extends beyond the filter tank itself. We approach every repair with a systems perspective, recognizing that filter problems often originate from or create issues with other pool components.

Integrated Diagnostic Checks We Perform:

Pump Performance Analysis: We verify that the pump is providing adequate flow and pressure for the specific filter type and size. An undersized or failing pump can mimic filter problems.

Plumbing Inspection: We check for suction-side air leaks, return line restrictions, and proper valve operation that might affect filter performance.

Control System Verification: For automated systems, we ensure timers, sensors, and controllers are properly calibrated and functioning.

Chemical Balance Assessment: We test water chemistry as part of our diagnosis, as severely imbalanced water can accelerate filter deterioration.

The Professional Repair Process: Structured for Success

Our systematic approach to pool filter repair ensures we address root causes rather than symptoms, providing solutions that last.

Phase 1: Comprehensive Inspection and Accurate Diagnosis

We begin with a detailed evaluation that includes:

Visual inspection of the filter tank, valves, and connections for cracks, corrosion, or leaks

Pressure testing at multiple points in the system to identify restrictions

Flow rate measurement to quantify circulation performance

Internal examination (after safe depressurization) of filter media and components

Historical analysis of filter maintenance and performance trends

This thorough investigation allows us to distinguish between simple maintenance needs and genuine mechanical failures.

Phase 2: Transparent Recommendations and Collaborative Decision-Making

Once we identify the issue, we provide clear options including:

Specific components requiring repair or replacement

Comparative costs of repair versus complete system replacement

Timeline for repairs and any necessary parts ordering

Potential upgrades that could improve efficiency or longevity

We believe an informed customer makes the best decisions for their pool and budget.

Phase 3: Precision Repair with Quality Components

Our repairs utilize:

Manufacturer-approved or superior aftermarket replacement parts

Chemical-resistant seals and gaskets designed for prolonged submersion

Proper tools and torque specifications for assembly

Attention to detail that ensures every component functions as intended

We never cut corners on parts quality or installation precision.

Phase 4: Verification, Testing, and Performance Optimization

After repairs are complete, we:

Conduct leak tests at operating pressure

Verify proper flow rates and pressure differentials

Ensure automatic functions (backwash cycles, air relief) work correctly

Provide guidance on optimal run times and maintenance schedules

Schedule follow-up checks when appropriate

Repair Versus Replacement: Making the Economically Sound Choice

Not every filter problem requires complete replacement. Our technicians provide honest assessments based on multiple factors:

When Repair is the Most Prudent Choice:

The filter tank is structurally sound with no cracks or significant weathering

Internal components are available and reasonably priced

The system is less than 75% through its expected service life

Repair costs are less than 40% of replacement cost

Energy efficiency can be restored to near-original specifications

When Replacement May Be Recommended:

The filter tank shows structural compromise (cracks, bulging, significant corrosion)

Multiple internal systems require simultaneous replacement

The filter is substantially undersized for the pool volume

Technological advances offer significant efficiency improvements

Repair costs approach 60% or more of replacement cost

The system has exceeded its service life expectancy

We consider not just immediate costs but long-term operational expenses, including energy consumption, maintenance requirements, and warranty coverage.

The Energy Efficiency Connection: How Proper Filter Repair Lowers Operating Costs

Energy Efficiency & Cost Savings

A frequently overlooked benefit of professional filter repair is its impact on energy consumption. According to industry studies, a clean, properly functioning filter can reduce pool pump energy usage by 15-30% compared to a compromised system. This occurs through several mechanisms:

Reduced Hydraulic Resistance: A clean filter with intact media creates optimal resistance—enough to trap contaminants but not so much that it forces the pump to work excessively. This “sweet spot” in pressure differential (typically 8-10 PSI increase from clean to dirty) allows efficient operation.

Improved Flow Dynamics: When water moves smoothly through undamaged filter internals, the pump can operate at lower RPMs while maintaining adequate turnover rates. For variable-speed pumps, this means more hours at efficient low speeds.

Shortened Run Time Requirements: A fully functional filter cleans water more effectively, potentially reducing the necessary daily run time to maintain clarity and chemical distribution.

Extended Equipment Life: Reduced strain on the pump translates to fewer repairs and longer service intervals for the entire circulation system.

The cumulative effect of these efficiencies often means the cost of professional filter repair is recouped through energy savings within a single swimming season, followed by ongoing reductions in operating expenses.

Specialized Applications: Residential, Commercial, and Unique Systems

Our repair expertise extends across all pool types and applications:

Residential Pool Repair: We understand that your home pool is an oasis for family and friends. Our residential services prioritize minimal disruption, clear communication, and solutions tailored to how your family uses the pool.

Commercial and Public Pool Compliance: Commercial filtration systems must meet stringent health department requirements for turnover rates and filtration standards. Our technicians are trained in these regulations and ensure repairs restore compliance alongside performance.

High-Volume and Specialty Systems: From vanishing edge pools requiring precise flow balance to saltwater pools with specialized corrosion considerations, we adapt our repair approaches to accommodate unique system requirements.

Aging Pool Restoration: Older pools with discontinued filter models present particular challenges. Our extensive parts network and mechanical expertise often allow us to repair systems that others would declare obsolete, saving substantial replacement costs.

Preventative Maintenance: The Best "Repair" is Prevention

While we specialize in repair services, we advocate for proactive maintenance to avoid many common filter problems:

Regular Service Schedule: We recommend professional inspection at least annually, coinciding with pool opening or before the peak season.

Owner Education: We teach customers proper pressure monitoring, cleaning techniques specific to their filter type, and signs of impending issues.

Winterization Services: Proper off-season preparation prevents freeze damage—a leading cause of cracked filter tanks and broken internal components.

Performance Benchmarking: We help establish normal operating parameters for your specific system, making deviations easier to spot early.

Why Choose Us for Pool Equipment Installation?

Certified Technicians

Unlike specialists limited to one filter type, our technicians are certified and experienced with cartridge, sand, and DE systems from all major manufacturers.

Advanced Diagnostic

We invest time in correct diagnosis, recognizing that the apparent problem is often a symptom rather than the cause.

Transparent Service

We maintain an extensive inventory of common replacement parts, minimizing downtime for standard repairs.

Follow up

Our repairs come with guarantees, and we schedule follow-up checks to ensure continued optimal performance.

FAQS

My pool water is cloudy but my pressure gauge reads normal. Could my filter still need repair?

Absolutely. Normal pressure readings with cloudy water often indicate a failure of the filter media itself, not a clog. In cartridge filters, this could mean torn pleats allowing unfiltered water to bypass. In sand filters, it may indicate channeling (where water creates paths through the sand bed) or broken laterals. In DE filters, torn grids or improper DE coating would cause this symptom. A normal pressure gauge can create false confidence while filtration efficiency plummets.

What's the difference between "dirty filter pressure" and "actual system problem pressure"?

Every filter has a “clean pressure” baseline (typically 8-12 PSI depending on system size). When pressure rises 7-10 PSI above this baseline, it’s time for routine cleaning. However, if pressure:

Rises abruptly (overnight or in days rather than weeks)

Doesn’t decrease after proper cleaning/backwashing

Fluctuates wildly during operation

Remains at clean pressure but water quality deteriorates

These patterns indicate mechanical issues requiring repair, not just maintenance.

I hear a gurgling or air-blowing sound from my filter. Is this a repair issue?

Yes, immediately. Air in the filter system typically indicates:

Suction-side leaks (before the pump)

Worn pump lid O-rings or drain plugs

Cracked pipe fittings on the pressure side

Faulty air relief valve on DE or cartridge filters

Water level too low in the pool

Air doesn’t just reduce efficiency—it can cause cavitation damage to pump impellers and prevents proper filtration as air pockets displace filter media.

My filter tank is sweating or has condensation. Is this normal or a concern?

Minor condensation on metal filter tanks during humid weather can be normal. However, excessive “sweating” or continuous condensation often precedes visible leaks and indicates:

Poor water circulation causing temperature differentials

High humidity combined with cold groundwater in underground plumbing

Early-stage cracks not yet leaking but allowing moisture penetration

In sand filters, this can indicate internal channeling creating cool spots

Have this inspected, as it often reveals developing issues before catastrophic failure.

How do you determine whether to repair or replace a component versus the entire filter?

We use a detailed decision matrix considering:

Age Factor: Components older than 75% of expected lifespan (typically 7-8 years for most filters) lean toward replacement

Cost Ratio: If repair costs exceed 50-60% of comparable replacement with warranty, replacement often makes more sense

System Compatibility: Older filters may not work efficiently with modern variable-speed pumps

Energy Efficiency: Newer filters can offer 15-30% energy savings, paying for themselves in 2-4 seasons

Multiple Failure Points: If three or more major components need simultaneous repair, replacement usually proves more economical long-term

Parts Availability: Discontinued models may make repair impractical